LCURE - PRO

LED UV curing technology has steadily evolved in the last 15 years from concept to reality thanks to various technological advancements in the world of electronics, lighting and Diode technology. Alpna’s L Cure is now a reality and a practical and serious alternative to Mercury UV system.

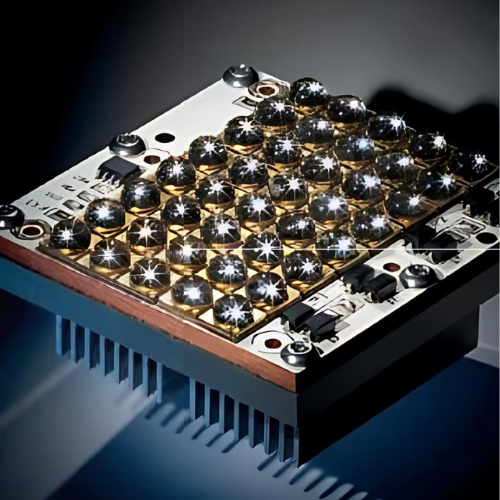

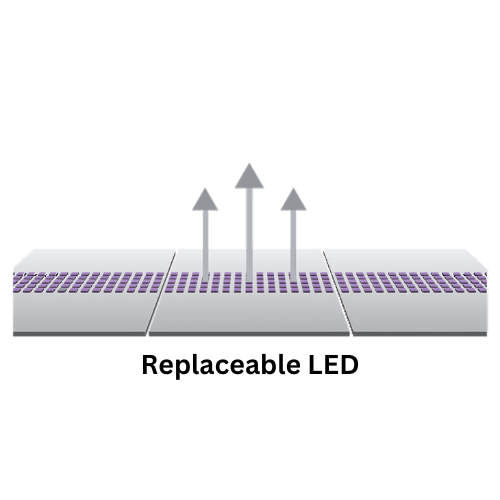

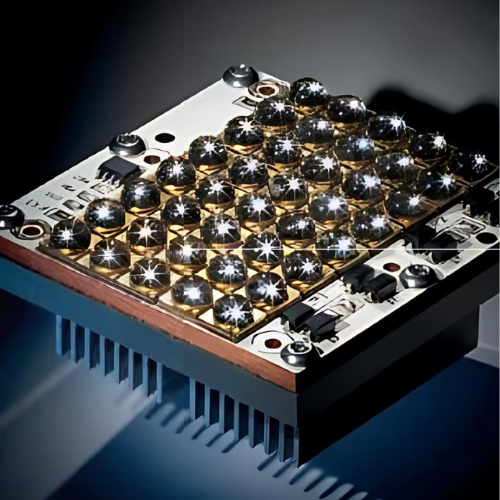

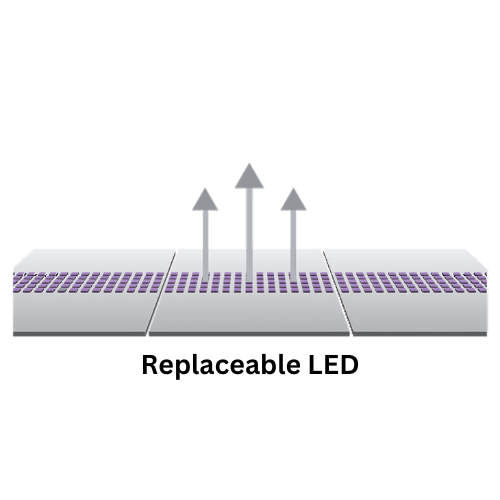

Alpna has adopted latest Chip on board technology in its current systems. COB offers modular construction as these can be stacked together linearly to achieve various lengths and configurations. The COB’s itself are state of art technology. The Diodes are sourced from best supplier from around the world and made into COB’s with on-board AC to DC conversion and temperature monitoring for safety. Each COB consists of 24 LEDs in rows of 3 each and is equipped with a 60 deg focal lens and includes 3 chips with a unit power of 1480mW @1500 mA. Therefore, each LED emits 16.45 W on a surface of 0.49 cm2 the maximum power is therefore 25 W/cm2 for complete curing of UV-based inks, varnishes, resins and adhesives in high-productivity industrial processes.

The continuous technological progress in LED production, through the use of module COB (Chip On Board) cards, makes it possible to achieve a highly selective and powerful emission of monochromatic UV irradiation

- AlGaN/InGaN LED chip technology

- Advanced High power COB based modular diodes

- Ultra-high brightness and efficiency

- Excellent thermal stability aided by liquid cooling

- 365-385-395-405 nm pure monochrome wavelengths

- Extended durability with lasting high perfor

- Zero ozone emissions

- AlGaN/InGaN LED chip technology

- Advanced High power COB based modular diodes

- Ultra-high brightness and efficiency

- Excellent thermal stability aided by liquid cooling

- 365 - 385 - 395 - 405 nm pure monochrome wavelengths

- Extended durability with lasting high perfor

- Zero ozone emissions.

LCURE - PRO

LED UV curing technology has steadily evolved in the last 15 years from concept to reality thanks to various technological advancements in the world of electronics, lighting and Diode technology. Alpna’s L Cure is now a reality and a practical and serious alternative to Mercury UV system.

Alpna has adopted latest Chip on board technology in its current systems. COB offers modular construction as these can be stacked together linearly to achieve various lengths and configurations. The COB’s itself are state of art technology. The Diodes are sourced from best supplier from around the world and made into COB’s with on-board AC to DC conversion and temperature monitoring for safety. Each COB consists of 24 LEDs in rows of 3 each and is equipped with a 60 deg focal lens and includes 3 chips with a unit power of 1480mW @1500 mA. Therefore, each LED emits 16.45 W on a surface of 0.49 cm2 the maximum power is therefore 25 W/cm2 for complete curing of UV-based inks, varnishes, resins and adhesives in high-productivity industrial processes.

The continuous technological progress in LED production, through the use of module COB (Chip On Board) cards, makes it possible to achieve a highly selective and powerful emission of monochromatic UV irradiation

CUTTING EDGE TECHNOLOGY

- Wavelength 385nm, 395nm and 405nm

- Curing Length available from 205mm to 1500mm

- Power Intensity – Upto 30 Watts/cm2

- Easy mounting and dismounting with use of quick connections for water and electrical lines

- Printing Speeds up to 200 meter/minute

- Easy to maintain

- Very low heat especially suitable for thermally sensitive substrates

- Pure UV emission for deep and complete curing

- Power saving compared to mercury UV

Highly Durable, LED

Water Cooled

Extermely Compact And Robust Design

Energy Saving

Advanced Optics For Deep Curing

High Quality After Sales Support

Intelligent Power Pack

CUTTING EDGE TECHNOLOGY

- Wavelength 385nm, 395nm and 405nm

- Curing Length available from 205mm to 1500mm

- Power Intensity – Upto 30 Watts/cm2

- Easy mounting and dismounting with use of quick connections for water and electrical lines

- Printing Speeds up to 200 meter/minute

- Easy to maintain

- Very low heat especially suitable for thermally sensitive substrates

- Pure UV emission for deep and complete curing

- Power saving compared to mercury UV

Highly Durable, LED

Water Cooled

Extermely Compact And Robust Design

Energy Saving

Advanced Optics For Deep Curing

High Quality After Sales Support

Intelligent Power Pack

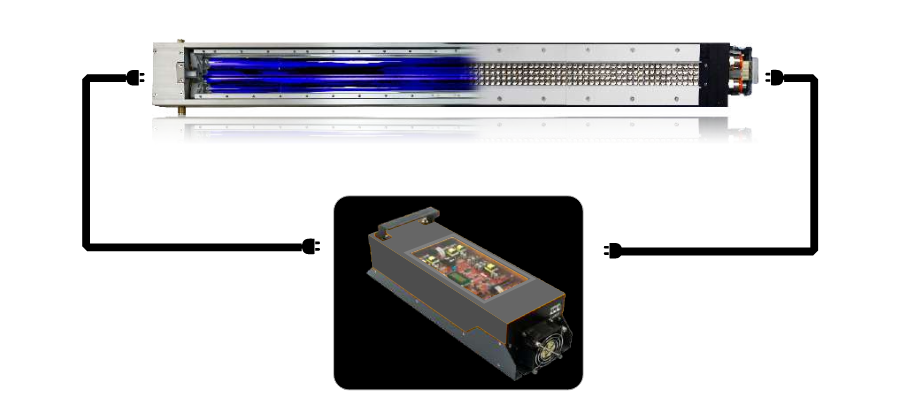

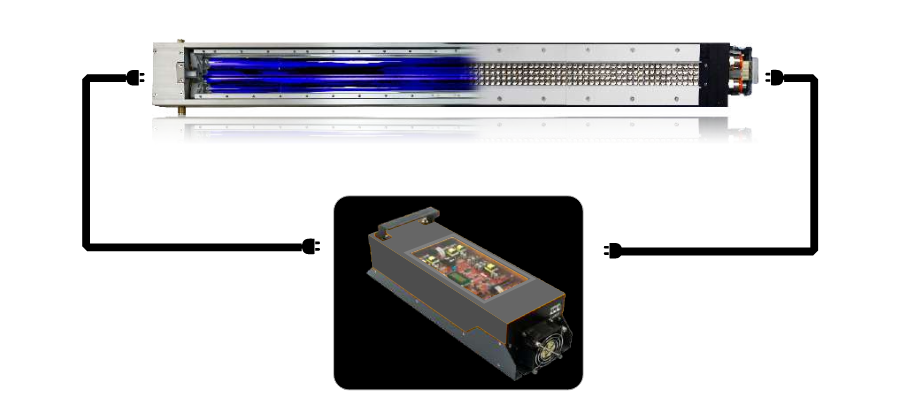

SMART-POWER-SUPPLY

On the fly quick swappable. The LED Power Packs are available in the COMBO version, which can control both conventional lamps and innovative UV LED with system control power supply system. AC power instead of DC with variable voltage control offers many advantages.

The software on board constantly monitors all the functions of the LED, as well as providing a complete diagnostic of the LED or the connected lamp. The alarm system instantly alerts and monitors for any errors or malfunctions.

As the size of the lamp increases, cables with a large cross-section, which is a significant element in the design of installations, will become indispensable for the power supply. It is not possible to control the distribution of currents in the individual clusters of LEDs unless several power supplies are used at the same time.

SMART-POWER-SUPPLY

On the fly quick swappable. The LED Power Packs are available in the COMBO version, which can control both conventional lamps and innovative UV LED with system control power supply system. AC power instead of DC with variable voltage control offers many advantages.

The software on board constantly monitors all the functions of the LED, as well as providing a complete diagnostic of the LED or the connected lamp. The alarm system instantly alerts and monitors for any errors or malfunctions.

As the size of the lamp increases, cables with a large cross-section, which is a significant element in the design of installations, will become indispensable for the power supply. It is not possible to control the distribution of currents in the individual clusters of LEDs unless several power supplies are used at the same time.

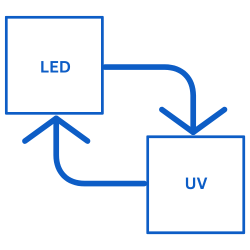

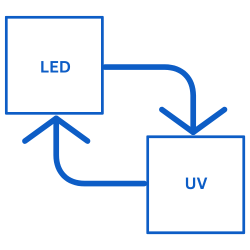

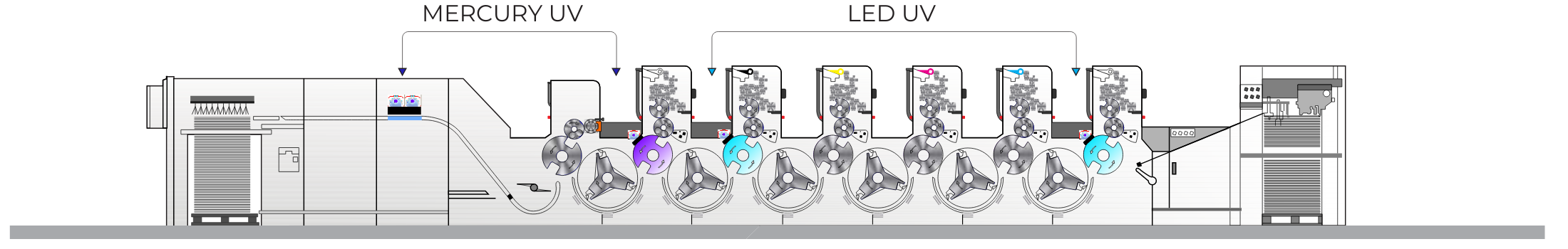

HYBRID CURE LED + MERCURY UV

HYBRID POWER SUPPLY

HYBRID CURE LED + MERCURY UV

HYBRID POWER SUPPLY

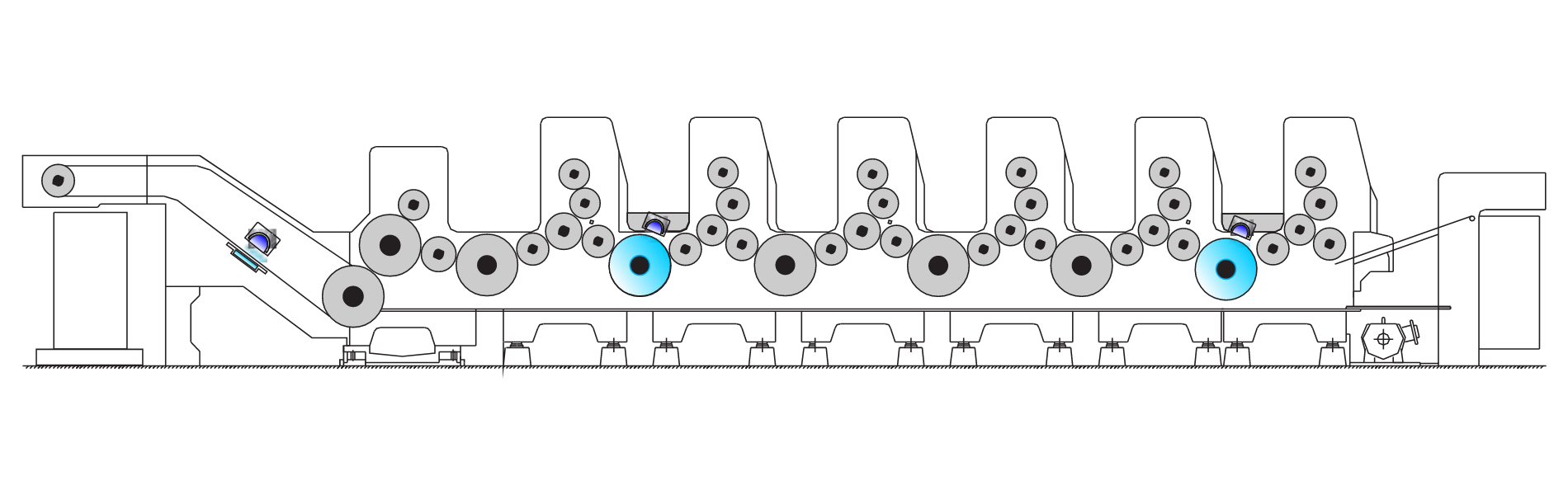

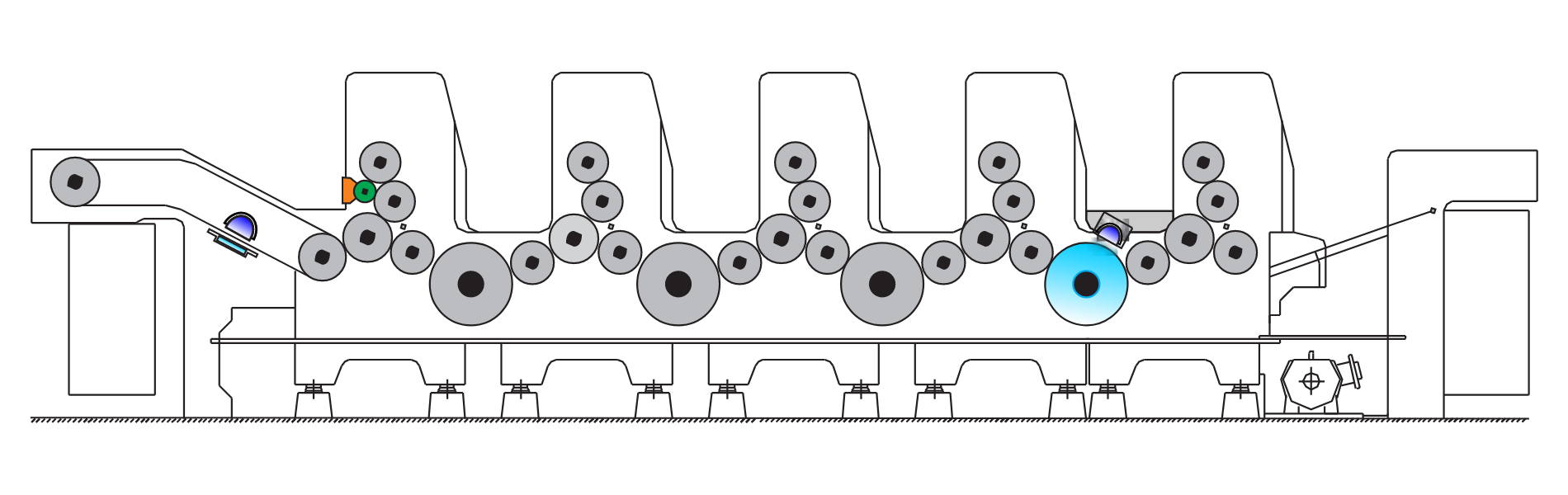

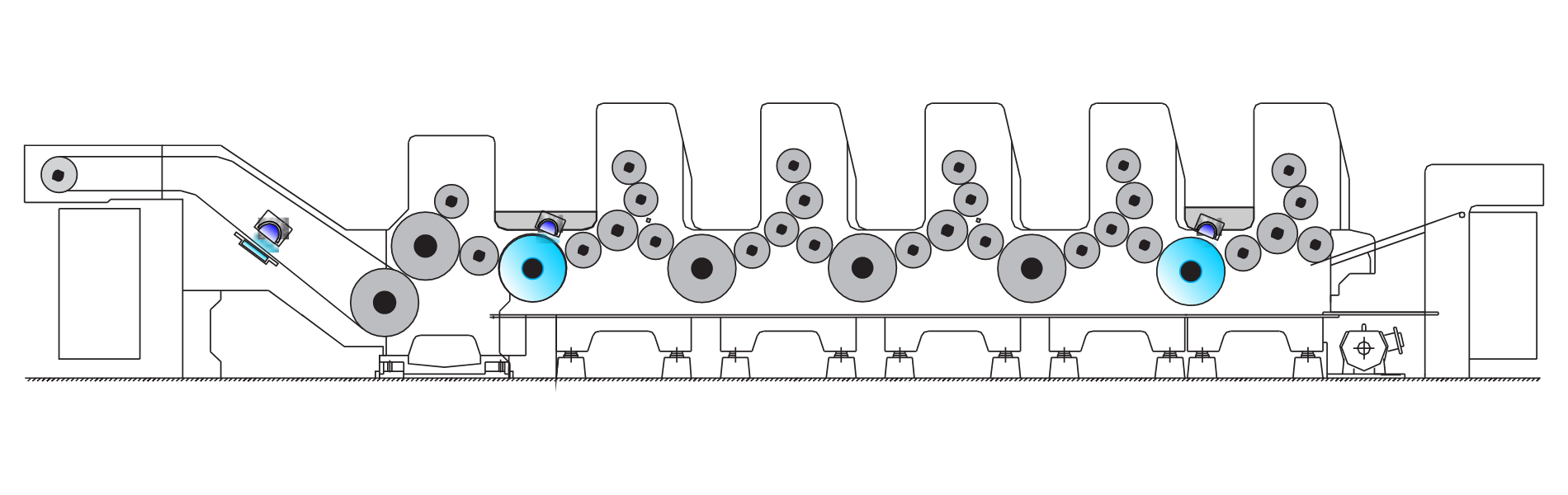

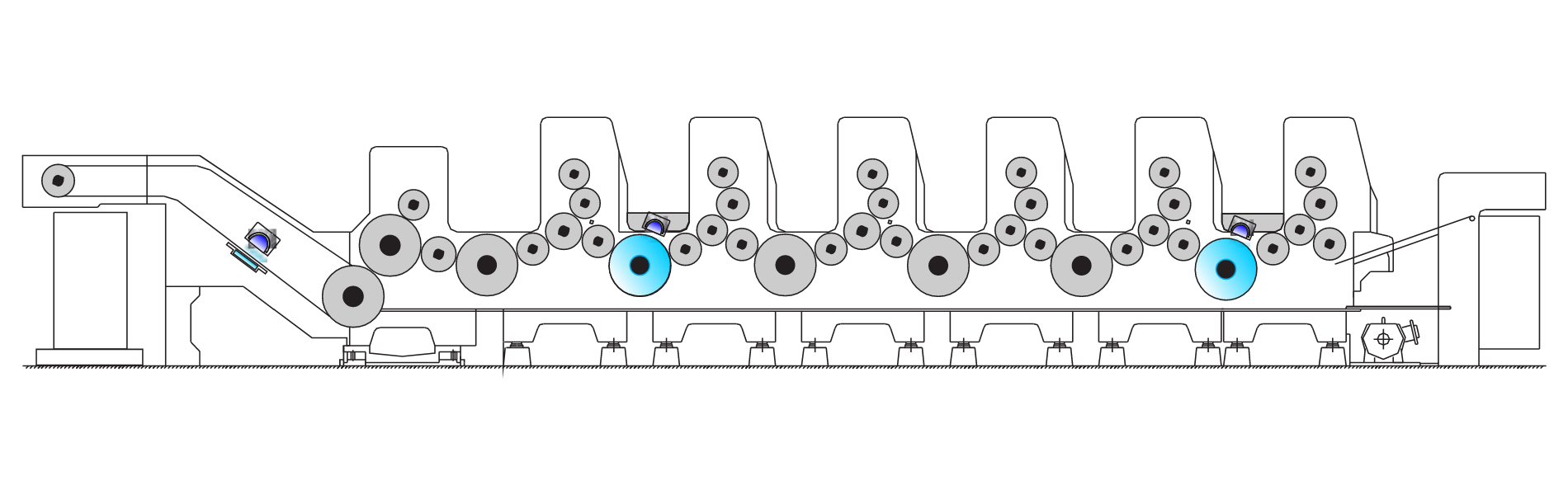

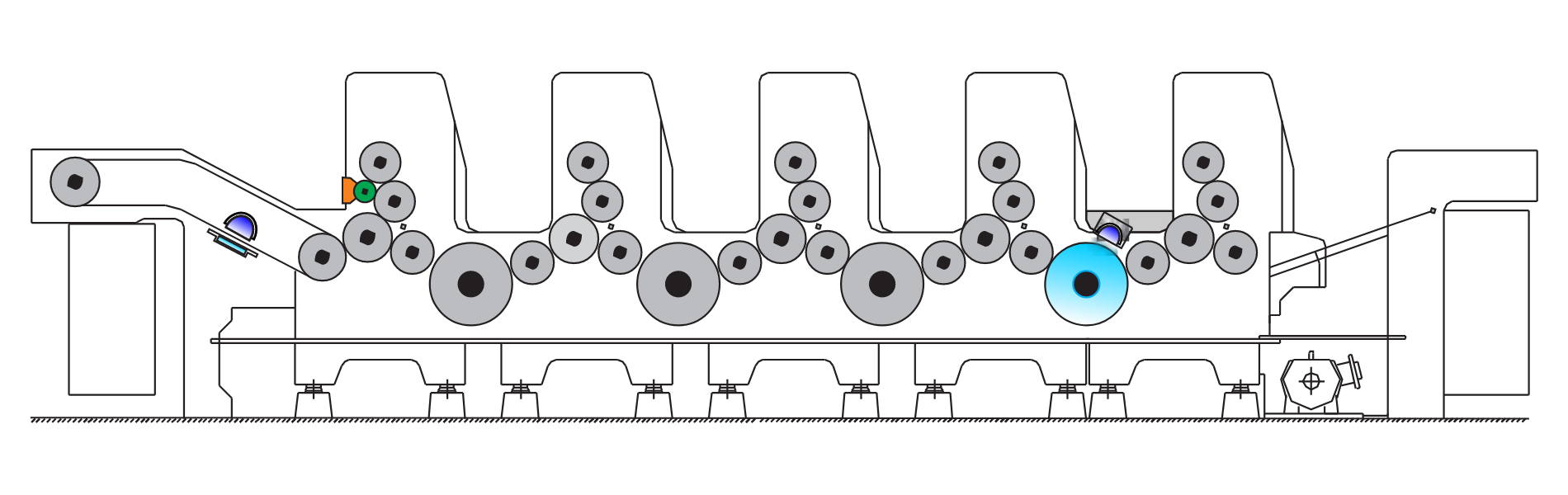

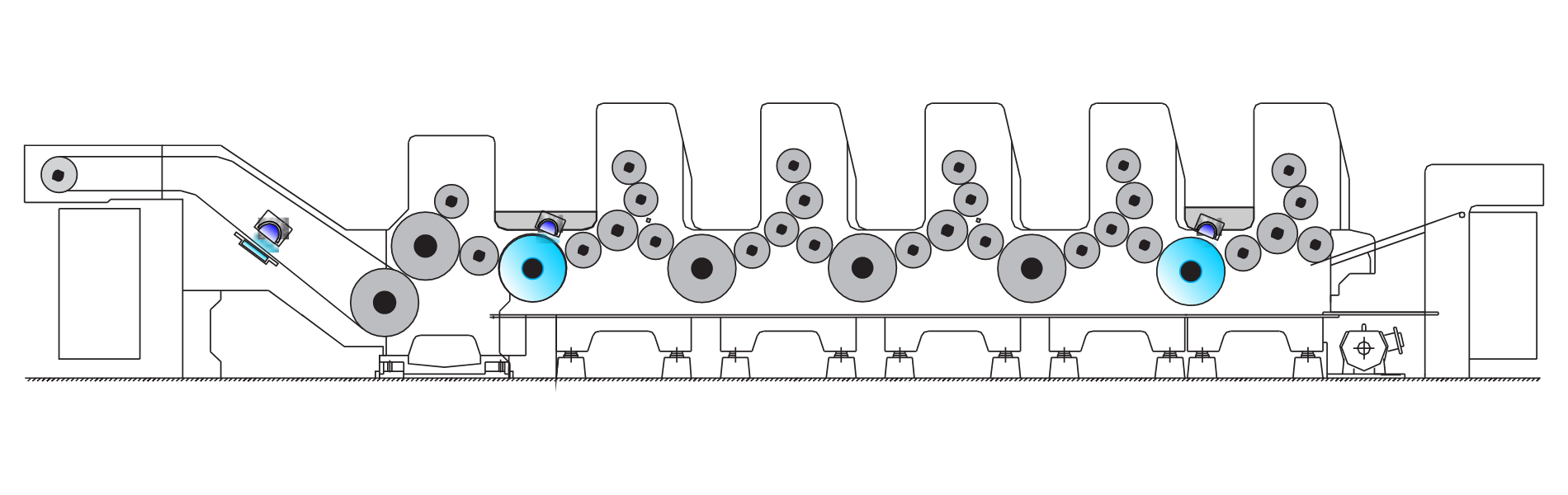

L-CURE CONFIGURATION FOR VARIOUS SHEET-FED PRESSES

L-CURE CONFIGURATION FOR VARIOUS SHEET-FED PRESSES

One ID + One EOP LED, Configuration on a Four Color Offset Press

One ID + One EOP LED, Configuration on a Five Color+Coater Offset Press

One ID + One EOP LED, Configuration on a Six Color+Coater Offset Press

One ID + One EOP LED, Configuration on a Four Color Offset Press

One ID + One EOP LED, Configuration on a Five Color+Coater Offset Press