Offline Drip-Off Coating | Full/Spot UV Coating | Aqueous Coating | Soft Touch Coating | HSL Coating and many more

SMART-COAT KIT

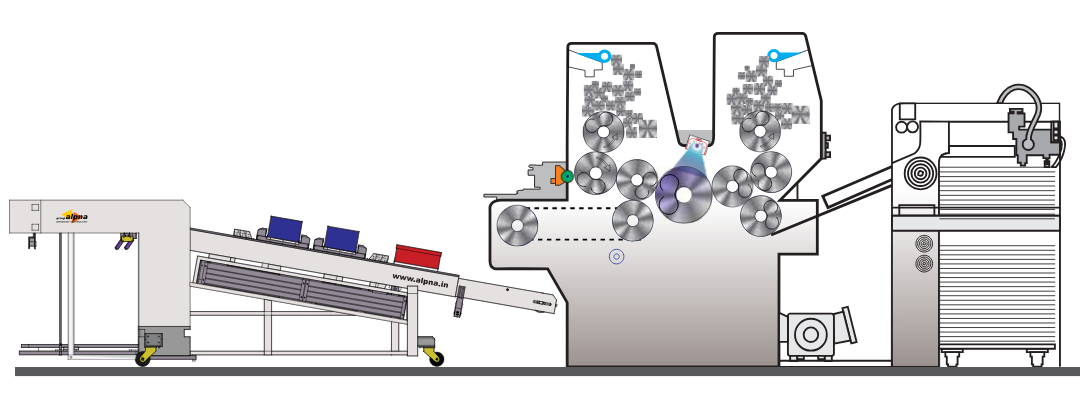

The Rhino-Dexa offer one-stop solutions to any kind of offline coating, such as gloss UV coating, matt/gloss UV coating for spot coating, drip-off coating, water-based gloss and matt coating, water-based primer coating, velvet-touch coating, blister medium coating for blister packs and barrier coating for food packaging.

The fully loaded versions offer CDB Anilox Coater, EPS based Interdeck UV and conveyorized UV / JET Driers with Auto Sheet Stacking.

This powerful platform is designed for heavy duty round the clock operations and it can handle medium to high volumes while continuously offering great flexibility of various coatings like Drip-Off, Spot UV/Aqueous, Primer Coatings etc.

High Speed up-to 10000 SPH

Easy to Operate

Fast Change Over Time

100% Satisfactory Results

Complete Coating Solution

Over 250 Installations Across India

SMART-COAT KIT

SMART COAT KIT offer one-stop solutions to any kind of offline coating, such as gloss UV coating, matt/gloss UV coating for spot coating, drip-off coating available with different texture options, water-based gloss and matt coating, water-based primer coating, velvet-touch coating, blister medium coating for blister packs and barrier coating for food packaging.

We use advanced technologies with CDB chambers from Tresu, Denmark. The technology also uses the servo precision sync technology, which is an automatic varnish circulator, and synchronisation with the offset platform of the conveyorisd system. The products come with superior lamp-head and reflector design. The products offer EPS and PLC-based operations for energy efficiency. The machines have detailed engineering designs, taking into consideration shopfloor pain areas, and focusing on productivity and safety aspects.

High Speed up-to 10000 SPH

Easy to Operate

Fast Change Over Time

100% Satisfactory Results

Complete Coating Solution

Over 250 Installations Across India

ADVANCED DRYING SYSTEM

ADVANCED DRYING SYSTEM

HIGH-SPEED DRYING TECHNOLOGY

C-Cure Conveyerised UV Dryers has been developed from many years of experience gained in design and production of over 2500 conveyerised UV dryers, in daily used world wide. Alpna UV dryers are Widely acknowledged as the most reliable and most efficient available. This precision has been achieved with extensive knowledge of discharged lamp requirement with optimum performance and the use of high quality power supplies.

- High speed drying in UV and aqueous coatings

- Electronic power supply to save 25% energy

- Touch screen, PLC control system

- Air cooled

- High speed automatic sheet stacker

- Heavy duty cast iron blower for maximum heat extraction and noise free operation

- Longer consumable life due to carefully designed sub systems

High degree of safety with circuit breakers with use of fuses, overload relays and jamming sensors

HIGH-SPEED DRYING TECHNOLOGY

C-Cure Conveyerised UV Dryers has been developed from many years of experience gained in design and production of over 2500 conveyerised UV dryers, in daily used world wide. Alpna UV dryers are Widely acknowledged as the most reliable and most efficient available. This precision has been achieved with extensive knowledge of discharged lamp requirement with optimum performance and the use of high quality power supplies.

- High speed drying in UV and aqueous coatings

- Electronic power supply to save 25% energy

- Touch screen, PLC control system

- Air cooled

- High speed automatic sheet stacker

- Heavy duty cast iron blower for maximum heat extraction and noise free operation

- Longer consumable life due to carefully designed sub systems

High degree of safety with circuit breakers with use of fuses, overload relays and jamming sensors

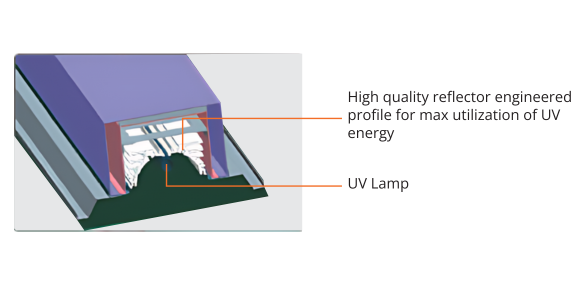

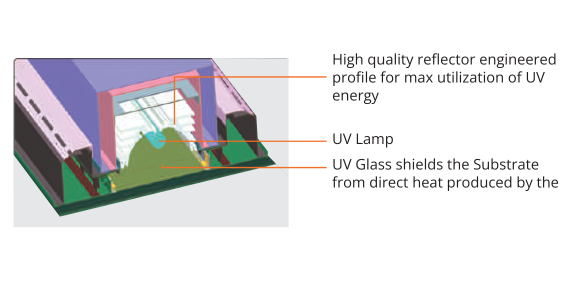

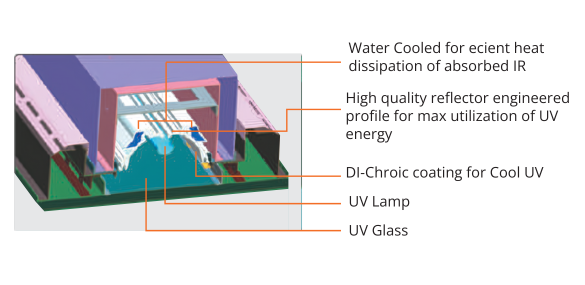

REFLECTOR TECHNOLOGY

Class-E-Reflector Assembly

Class-I-Reflector Assembly

Class-II-Reflector Assembly

INTERDECK UV SYSTEM

- Air-cooled UV lamp-heads for minimum heat transfer

- Quick connections for air & electricity

- Advanced diagnostics for fault detection

- EPS type power-pack for power saving and precise step-less intensity control

- Indigenous cassettes design with very compact dimensions while meeting high performance parameters

INTERDECK UV SYSTEM

- Air-cooled UV lamp-heads for minimum heat transfer

- Quick connections for air & electricity

- Advanced diagnostics for fault detection

- Heat extraction system for minimum heat built-up

- EPS type power-pack for power saving and precise step-less intensity control

- Indigenous cassettes design with very compact dimensions while meeting high performance parameters

Electronic Power Supply (EPS)

- Power supply UV intensity control : 3 Phase, Step-less Frequency (10% to 100%)

- Stand-by Power Mode : Minimum 10%

- Advanced Diagnostics : Digital display for fault detection

- Weight & Size : Light & Compact

SUPERIOR COATING TECHNOLOGY

SUPERIOR COATING TECHNOLOGY

SMART – COAT CDB ANILOX COATER

- CBD chamber from leading european make – Tresu

- Precise control of coating weight

- Make ready time measured in minutes elimination of foaming and blisters uniform quality at even higher speeds

- Minimal manual intervention

- Safer, vapor-free and cleaner working conditions

- Ceramic anilox roller for consistent transfer of coating weight

- Analog dial gauges for uniform and quick pressure setting

- Enclosed coating circulation system with diaphragm pump

- Clean, run and flushing cycles with quick connectors quick anilox roller change

SMART – COAT CDB ANILOX COATER

- CBD chamber from leading european make – Tresu

- Precise control of coating weight

- Make ready time measured in minutes elimination of foaming and blisters uniform quality at even higher speeds

- Minimal manual intervention

- Safer, vapor-free and cleaner working conditions

- Ceramic anilox roller for consistent transfer of coating weight

- Analog dial gauges for uniform and quick pressure setting

- Enclosed coating circulation system with diaphragm pump

- Clean, run and flushing cycles with quick connectors quick anilox roller change